24 Jan 2022

The basics of Asphalt Mix Testing

This article will explore the fundamental aspects of performance asphalt mix testing. We will explain why asphalt mix testing is necessary, how it came about, and what options are available for different testing needs.

Why do we test asphalt?

Asphalt mix testing is critical for increasing the lifetime of a pavement. Weak asphalt mixtures can cause rutting and cracking, so to avoid premature pavement failure causing expensive damage and traffic safety issues, we must be able to adequately measure all the properties of the materials. This means that asphalt mix testing equipment must be able to perform quality control and quality assurance tests to determine which mixtures will succeed and which ones will fail.

In order to determine which mixtures will perform well, test conditions must accurately represent and simulate real road conditions – this is where performance testing comes into play.

Example of rutting (left side) and cracking (right side) distresses.

The rules of the game have changed

In the last 50 years, a lot has changed. Traffic volume has increased and so has the volume of modern cars. As such, asphalt mixtures need to be adjusted accordingly.

To further complicate things, not only have traffic conditions changed, but so have the materials being used. Oil economics and other global factors have affected the consistency of asphalt binder, and nowadays there are new construction materials available. In the past, mixtures were more basic – aggregates, binders and filler were the only players of the game. Today, we use other materials like polymers and additives; not to mention we also have recycled asphalt mix, marginal materials and recycled tyre rubber.

Think of it like baking a cake - the more ingredients there are, the more complicated the recipe. Therefore, the need for performance testing is simple: tests need to better represent real traffic loads and be able to measure fundamental material properties.

Performance testing VS traditional testing

The difference between performance testing and traditional testing lies in their ability to accurately predict field performance. In traditional testing, test conditions such as load, speed, and temperature are not necessarily an accurate depiction of real road conditions. This significantly reduces the reliability of the test, meaning that the pavement is more susceptible to failure.

In performance testing, we can actually change the test conditions to mimic real conditions. At CONTROLS, our products are designed to give you maximum control over specific test conditions. For example, our dynamic asphalt mix testing machines have cabinets that can change the temperature from -50 °C to +80 °C, because each property needs a specific temperature.

Performance Testing

What are the main parameters we want to measure in performance testing?

There are many parameters that must be taken into consideration, but there are three significant parameters that we believe are absolutely critical to measure:

Parameter 1: Stiffness / Modulus of Elasticity (MoE)

The first and arguably most crucial parameter is stiffness, also known as the dynamic modulus. Dynamic modulus refers to the elasticity of the materials; it is the ratio between the load applied and the resilient deformation of the material.

Asphalt mix is a visco-elasto-plastic material. This means that stiffness is dependent on two factors: temperature and frequency of application. Temperature dramatically changes the material’s mechanical behaviour. Mechanical behaviour can also be affected by the frequency of application. If the load is applied fast, the material becomes stiffer. If it is applied slowly, the material becomes softer and weaker.

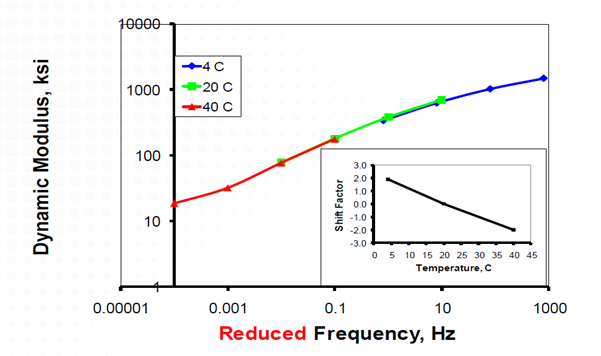

A full elaboration of the relationship between stiffness, temperature and frequency is demonstrated in the Mastercurve:

Graphical elaboration of a Mastercurve to describe dynamic modulus with different temperatures and loading frequencies.

Parameter 2: Resistance to Fatigue

The second important parameter is cracking i.e., resistance to fatigue. Fatigue is the fact that materials weaken when exposed to repeated wheel loads (traffic). The result of fatigue failure is fatigue cracking – you might have heard the term “alligator cracking”. This type of cracking occurs when the pavement has been stressed to its life limits due to repeated load applications.

Example of alligator cracking.

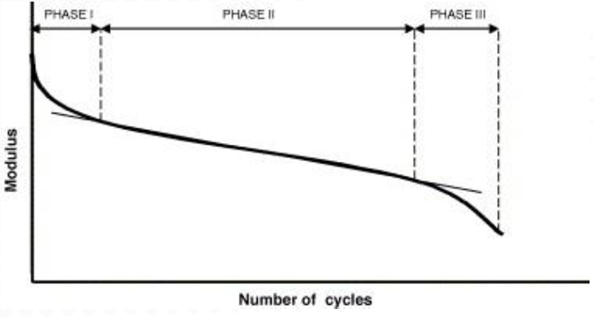

So, to understand a material’s resistance to fatigue, we must measure its elasticity over time. The typical behaviour of a fatigue test is illustrated in the graph below:

The more horizontal the curve, the more resistant to fatigue the material is and the better that material is.

Parameter 3: Rutting / permanent deformation

The last crucial parameter to test is rutting. Rutting faces the same dilemma as fatigue: after repeated traffic loads, the material properties change and weaken. However, in this case, rather than the pavement cracking, it loses its shape and smoothness. An unstable pavement develops ruts, ripples, and other signs of permanent deformation. Performance testing is designed to prevent these damages from occurring.

Dynamic Testing Machines

Now that the fundamentals of performance testing have been covered, what choices do we have for actually performing these tests?

First, we have Universal Testing Machines (UTM). This type of machine is a single unit machine that is able to perform multiple tests. This first-generation machine is our dynamic testing option, and its frame size is compatible with a wide range of accessories.

Universal Testing Machines (UTM).

Next up we have the Asphalt Mixture Performance Testers (AMPT). This second-generation dynamic testing machine is more suited to quality control and is more user-friendly than the UTM.

Asphalt Mixture Performance Tester (AMPT Pro).

Finally, we have the Compact Modular Asphalt Mix Tester, as AsphaltQube. This machine merges the capabilities of the UTM with the AMPT. This product is able to perform multiple tests like the UTM, but with the compact, user-friendly approach of the AMPT.

Compact Modular Asphalt Mix Tester

Something that these dynamic asphalt testing machines have in common is that they share the same controller and software. Let’s explore these features in more detail.

IMACS2 Controller

Following IPC Global’s invention of the IMACS Controller in the early 2000s, we have since developed the IMACS2 – the most advanced controller and data acquisition system in our industry.

The first, most noticeable difference between these two controllers is that the IMACS2 now has a touch screen display, making it much more user-friendly. Maintenance and basic control operation can be done via the touch screen.

The second important feature of the IMACS2 is its smart “plug and play” transducer. One of the downfalls of the original IMACS is that its configuration was fully manual. This meant that if the test configuration was wrong, so was the test performance. With the smart ‘plug and play’ transducer, the controller (i.e., the software) automatically recognises the channel when you connect the channel to each plug. This in turn makes it a smart channel, resulting in less room for error.

If you’re wondering whether these new technologies are compatible with older models, the answer is yes. One of the great advantages of these products is their cross-compatibility with IMACS and all UTS software. It is entirely possible to make a smooth transition between old controllers and new controllers, and old software and new software.

UTS Neutron Software

Following the improvement of our controllers, we also developed new software. The UTS Neutron is more powerful than ever and overcomes the limitations of the current UTS software. Perhaps its biggest advantage is its customisable interface for all testing needs. While the old software was only available in English, the UTS Neutron is setup in multiple languages – including custom language configuration.

The new UTS Neutron software also has three license levels to meet all user types:

By having the option to buy different licenses, you have the ability to fully customise the software to suit your testing requirements. Whether your focus is researched-based or in quality control, the UTS Neutron software can be tailored to your needs. The software also has configurable access rights for any user type, for example quality control operator, lab manager, and senior engineer to name a few.

UTS Neutron product features:

- Familiar UTS layout but enhanced and more intuitive

- Library of pre-programmed test modules complying with the main international standards eg. EN/ASTM/AASHTO

- Basic suite included with all IMACS2-based IPC Global dynamic testing machines

- Simple interface for routine quality control users who want to run a test with minimal mouse clicks

- Multiple languages – supplied with English, Chinese, Polish and Spanish languages plus customised language configurator tool

- Painless migration from IMACS to IMACS2. Users can import existing UTS data to generate new reports

- Robust reporting and easy custom test creation

- Graphic step-by-step test editor

- Possibility to edit and save user-defined test sequences and procedures

- Comprehensive graphic programming functions with in-built easy to use drag and drop icons It’s clear that in many cases the Asphalt Mix Testing is a complex process, that requires expertise and reliable machines.

It’s critical to invest in proper asphalt mix specimen preparation and testing machines, to avoid the unnecessary costs and risks associated with these assets.

For this reason, at IPC Global, we are continuously working to improve our asphalt mix testing machines, keeping our firmware and software updated to the latest specifications, and providing the most advanced consultancy services to help you choose the best testing solution. If you need any additional information, please feel free to contact us.