The ductility test is performed for determining the ductility of bituminous materials by measuring the elongation before breaking when two ends of briquette specimens are pulled apart at a specified speed and temperature.

This model fully satisfies and exceeds ASTM D113, ASTM D6084, AASHTO T51 and EN 13398 requirements. A water chiller (see accessories) is ideal for this and may already be available in the laboratory but mains water can also be used. If the ambient temperature goes over 25° C, as in the tropical areas, and cold mains water is not available, the use of a water chiller is mandatory.

Water bath

Insulated stainless steel water bath with a heating system located over the entire base surface and a cooling coil (for connection to water mains or chiller) distributed over the three side walls assuring temperature uniformity without water turbulence inside the bath. All parts in contact with water are made of stainless steel.

Carriage displacement

Double-screw rods and mobile carriage enable test speeds from 5 to 100 mm/min. The system also permits the fast return of the carriage at the end of the test (500 mm/min) to reduce dead time and increase productivity. The carriage return is automatic so manual intervention is not required.

Temperature control

- A closed-loop PID system assures constant temperature

- Plate-type base heaters give better temperature uniformity

- The thermoregulation system is based on controlling the heater (which increases the temperature of the bath) and the flow rate of the cooling coil (which decreases the temperature). This important feature assures control of the temperature within strict limits and permits the use of suitable standard water chillers

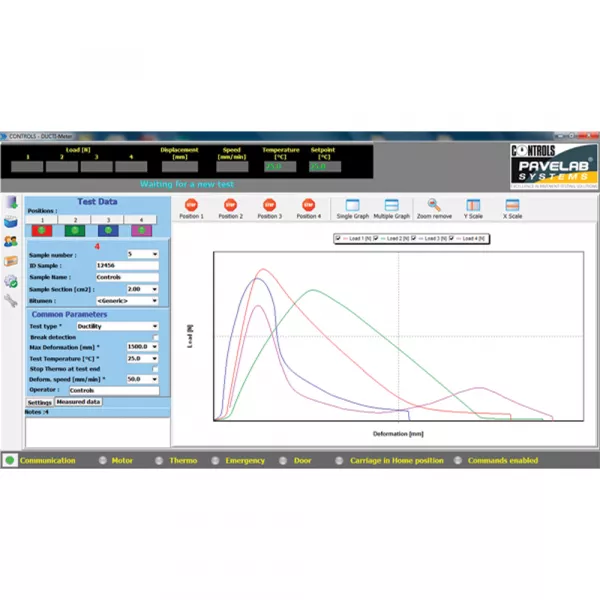

Machine control and elongation measurement

Control panel with digital display to set the testing speed: 5 to 100 mm/min, with the carriage return function. Elongation measurement by encoder.

The machine can be completed with a transparent cover.

- 4 tension line (briquette capacity) x 1500 mm

- Easy and free access to the large testing space

- Closed-loop PID temperature control system

- Stainless steel insulated water bath

- Exclusive in-built thermoregulation system compensating the exchange of heat and cooling, resulting in a very strict temperature control, optimized by the connection to chiller (optional)

- Adjustable speed range from 5 to 100 mm/min

- High carriage return speed of 500 mm/min for greater productivity

- Elongation measurement by encoder read on display

- ASTM D113

- EN 13398

- AASHTO T51

- ASTM D6084

|

Models

|

81-PV10A02

81-PV10A04

|

|

Conforms to Standards

|

EN 13398 ASTM D113 ASTM D6084

AASHTO T51

|

|

Machine control by

|

Digital display panel

|

|

Thermostatically controlled

water bath temperature

|

25°C

|

|

Temperature control system

|

Heater and cooling coil for connection to cold water or water

chiller

|

|

Structure

|

Stainless steel tank

|

|

Briquettes capacity

|

4

|

|

Max carriage travel

|

1500 mm

|

|

Testing speed

|

Adjustable from 5 to 100 mm/min

|

|

Elongation measurement by

|

Encoder (linear scale)

|

|

Carriage return speed

|

500 mm/min

|

|

Power rating (approx.)

|

1200 W

|

|

Transparent cover

|

As optional

|

|

Overall dimensions

|

(l x d x h) 2434 x 412 x 385 mm

|

|

Weight approx.

|

100 kg

|

81-PV10A02

DUCTIMETER, Ductility machine, 4 briquettes capacity, 1500 mm carriage travel. Cover not included. 230V/50-60/Hz/1ph

81-PV10A04

DUCTIMETER, Ductility machine, 4 briquettes capacity, 1500 mm carriage travel. Cover not included. 110V/60/Hz/1ph

81-B0141

Ductility mould to EN 13398

81-B0141/A

Briquette mould conforming to ASTM D6084 and AASHTO T300

81-B0141/B

Briquette mould conforming to ASTM D113 and AASHTO T51

81-B0141/E

Briquette mould conforming to EN 13589

81-B0142

Ductility mould plate

81-PV10010

Support base for ductility machines

81-PV1002

Water chiller, flow rate 6 l/min at 1 bar, 2°C min. temperature. 1200 W cooling capacity. 230V/50-60Hz/1ph

81-PV10030

Cover for DUCTI-Meter Ductility machine

81-PV1004

Water chiller, flow rate 6 l/min at 1 bar, 2°C min. temperature. 1200 W cooling capacity. 110V/60Hz/1ph