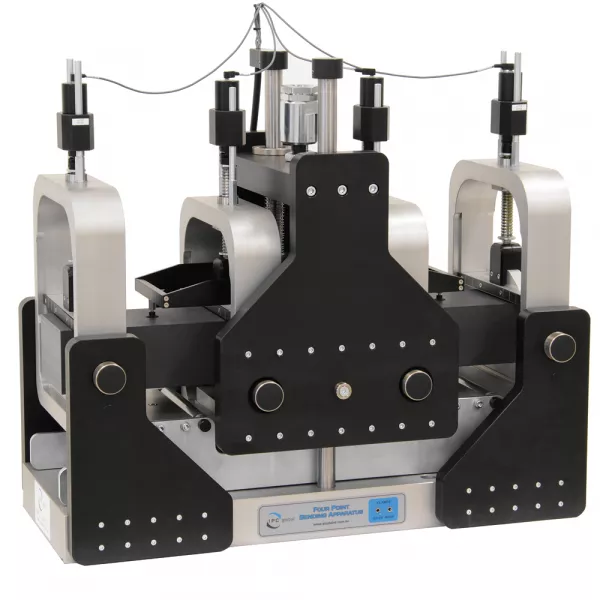

To perform Four Point Bend test

- Innovative “floating straight-edge” on specimen transducer displacement measurement eliminates errors

- Optional fixed point strain measurement referring from outer pivots

- Designed to subject an asphalt specimen to four point bending with backlash free rotation and horizontal translation of all load and reaction points

- Sinusoidal or haversine controlled strain or controlled stress loading

- Controlled force, motorized specimen clamping

- Loading frequency up to 60 Hz

- Non-linear regression data fitting ensures reliable determination of phase and modulus

- Can be used with existing UTM systems

- Cost effective solution for high volume testing

- Specimen laterally positioned by hand using etched lines as visual guide for two specimen sizes, nominally 50 and 63.5 mm in width

- Vertical clamping of the specimen is achieved by servo-motor driven ball screws, which are operated continuously during the test to take up the compliance of the specimen at the clamping surfaces

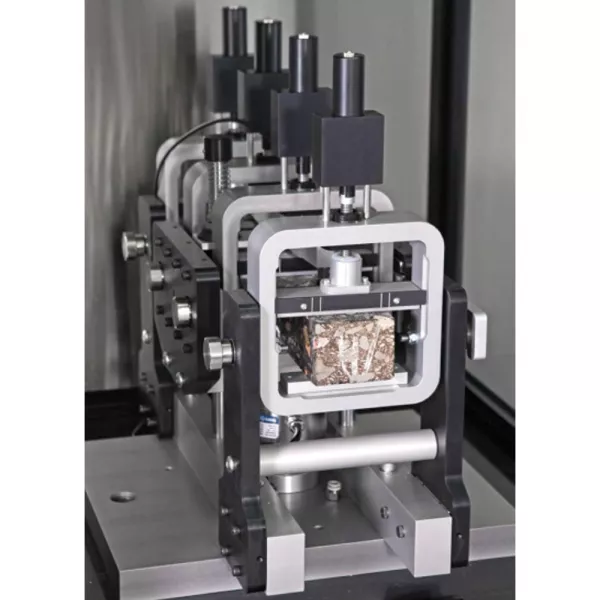

Extra Large Four Point Bend Jig

- Innovative floating on-specimen transducer eliminates errors caused by frame compliance

- Backlash free rotation and translation on all load and reaction points

- Controlled force and motorized specimen clamping

- Specimen rollers with pneumatic lift and lowering for easy loading of specimen

- Automated self-aligning specimen yokes for easy specimen insertion

- Specimen roller with pneumatic lift and lowering provide the user with easy test set-up across a range of extra-large specimen sizes

- Vertical clamping of the specimen is achieved by servo-motor driven ball screws, which are operated continuously during the test to take up the compliance of the specimen at the clamping surfaces

- Loading frequency: up to 60 Hz (load limitations apply at higher frequencies)

- Load capacity: up to 10 kN dynamic

- Specimen size (h x w x l): 70 (max) x 80 (max) x 380 mm

- Yoke alignment tool for specimen: 50 x 50 x 355.5 mm (h x w x outer span centers), 70 x 70 x 420 mm (h x w x outer span centers)

- Dimensions (h x w x d): 455 x 460 x 230 mm

- Weight: 35 kg

Extra Large Four Point Bend Jig

- Dimensions (h x d x w): 790 x 435 x 890 mm

- Weight: 210 kg

- Load capacity: up to 25 kN dynamic

- Specimen size (l x h x w): 790 (min) x 100-160 x up to 200 mm

- Yoke alignment tool for specimens: 740 mm (outer span centers), 247 mm (inner span centers)

- Air supply: clean, dry air at 700 kPa (specimen loading only)

79-PV70400

Four Point Bend Jig for UTM-30 for 355.5mm and 420mm (outer span centres) specimens. including Load Cell (+/-15kN w/ (ILC), LVDT (+/-0.5mm) w/ ILC, Yoke Alignment Tool for 355.5 mm (outer span centres) x 50mm x 50mm specimens

79-PV70402

Four Point Bend Jig for UTM-16P for 355.5mm and 420mm (outer span centres) specimens. Including LVDT (+/-0.5mm) w/ ILC, Yoke Alignment Tool for 355.5 mm (outer span centres) x 50mm x 50mm specimens

79-PV70440

XL Four Point Bend Jig for 740 mm (outer span ntres), 247 mm (inner span centres), suitable for M-130XL. includes: -1x XLFour Point Bend Jig (for UTM systems) -1x LVDT (+/-1mm) w/ In-Line Conditioner (ILC) -1x Yoke Alignment Tool

79-PV72101

AST Four Point Bending Jig for 355.5mm and 420mm (outer span centres) specimens, including Yoke Alignment Tool 355.5 mm (outer span centres) x 50mm x 50mm specimens