The Automatic Ring and Ball Tester allows fully automatic performance of softening point determination of binders conforming to most common international Standards.

Two binder specimens, cast in shouldered brass rings, are heated at a controlled temperature rate in a water or glycerol bath while each supports a steel ball. The softening point corresponds to the average temperature at which the two specimens soften enough to allow each ball, enveloped in binder, to fall 25mm, automatically detected by a calibrated light barrier.

Full Conformity

The Automatic Ring and Ball Tester fully complies with the temperature heating rate, displaying in real time the gradient and its deviation from the theoretical one. The tester saves the gradient and softening point results on the internal memory or onto a USB pen drive. You can export the temperature / time data in real-time to your PC or manage it with the optional PC software.

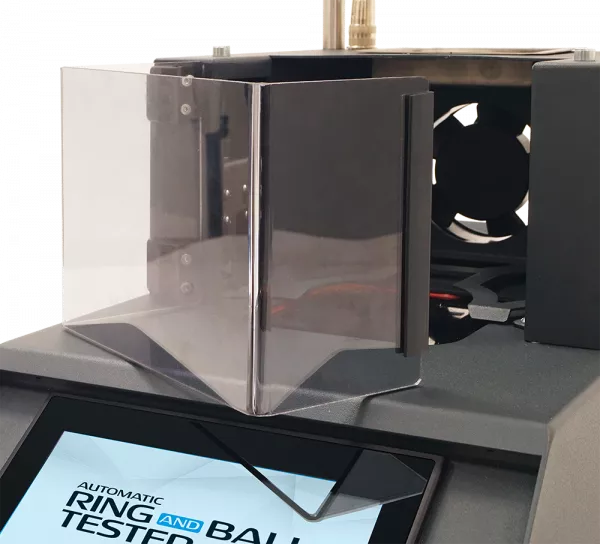

Improved Safety

The hotplate is fully sealed, so it cannot be damaged or affected by possible water or glycerol leakages, or if the beaker breaks. At the end of the test, the hotplate is automatically switched off and the integrated cooling fan enabled, improving the beaker cooling operations and reducing risks for the operator. The front transparent cover reduces the risks coming from accidental water or glycerol spilling from the beaker.

Standard Outfit

The apparatus is supplied complete with outfit for softening point of bituminous materials (two rings, two steel balls, two centering devices, support frame, 600ml beaker, PT100 probe, sample preparation plate and magnetic stirrer).

- Fully automatic softening point determination. The apparatus automatically applies the temperature gradient and detects the specimen position with light barriers, recording the softening point.

- 7’’ color touchscreen display, with multiple preset and custom testing procedures, allowing realtime display of the temperature / time graph on display or PC (with optional software).

- Inbuilt cooling fan, automatically enabled at the end of the test, to reduce the beaker cooling time.

- Removable transparent front cover, protecting the operator from accidental hot water or glycerol splashing or accidental contact with the hot beaker and plate.

- PT100 probe holder and drip tray for specimen holder, complete with handle, improving beaker positioning operations.

- Possibility to perform user-defined tests with maximum temperature up to 250°C.

- EN 1427

- ASTM D36

- AASHTO T53

- JIS K 2207

- IP 58

Test places: 2

Temperature range: up to 250°C

Temperature probes:

PT100 probe, , range -30 +350°C, 0.1°C resolution, ±0.2 °C accuracy

K thermocouple for hotplate monitoring range from 0°C to +1000°C, 0.1° resolution

Stirrer speed: from 0 to 200 rpm

Safety features:

Integrated cooling fan

Removable front protection cover

Temperature warning icon

Included PT100 probe holder and drip tray for specimen holder

Electronic controller specifications:

7” color capacitive touch screen graphical display, 16M color and 800 x 480 px resolution

Possibility to set up to 10 personalized test profiles

Possibility to program used custom tests with user defined end test conditions (up to 250°C) and temperature gradient up to 6°C/min

Display of temperature/time graph in real-time, and softening point temperature of the two specimens

Possibility the set the language among 14 pre-set languages

Connections and memory:

RS232 for PC connection (optional software)

USB for memory stick

Internal memory, storage up to thousands tests.

Power supply: 110 V or 230 V, 50 Hz/60 Hz, 1600W Dimensions: 295 mm x 465 mm x 430 mm (W x D x H)

Weight: approx. 13.7 kg

81-PV0144

Automatic ring and ball apparatus. 230V, 50-60Hz, 1ph

81-PV0144/Z

Automatic ring and ball apparatus. 110V, 60Hz, 1ph

81-PV0145/1

Brass ring (one piece)

81-PV0145/2

Steel ball

81-PV0145/3

Ball centering guide (single piece)

82-P0172/1

Serial cable for printer connection.

81-PV0144/2

Ring holder assembly for 81-PV0144 and 81-PV0144/Z