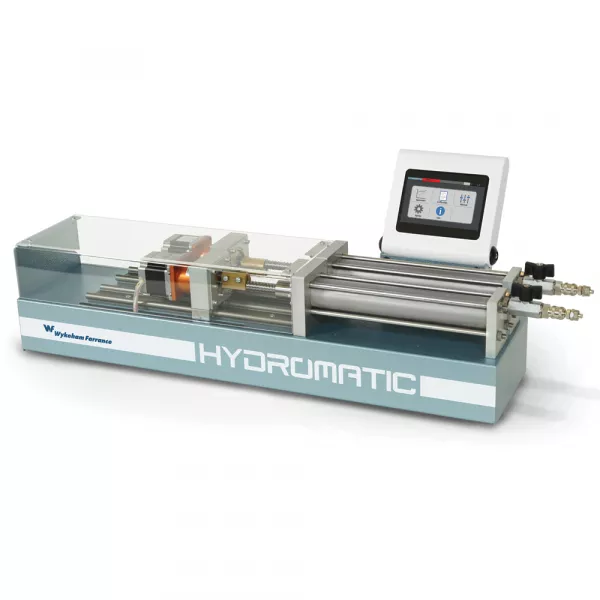

Hydromatic standalone is a general-purpose water pressure source and volume change controller. It is driven by a stepper motor, which enables the unit to measure the volume change. The unit consists of a hydraulic piston, driven by a low friction screw and gearbox, mounted on a ball-slide, and is managed under closed-loop control by the built in data acquisition and 6” touch-screen colour control panel.

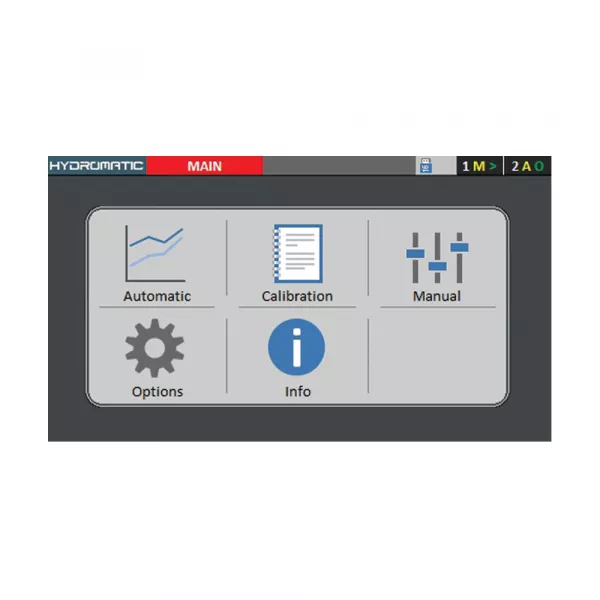

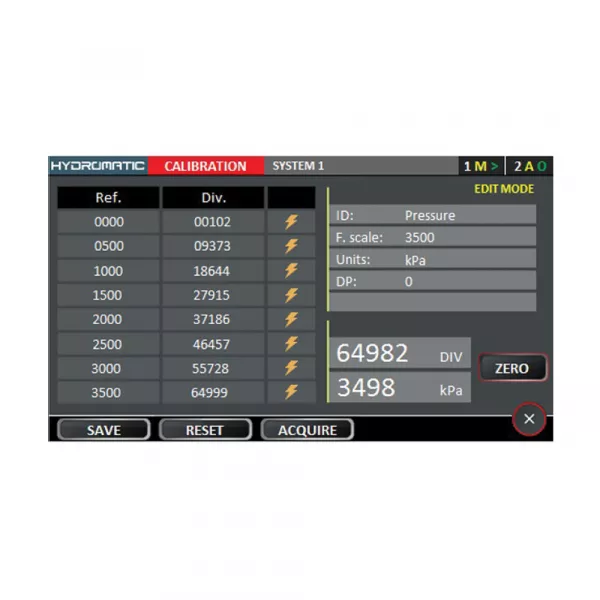

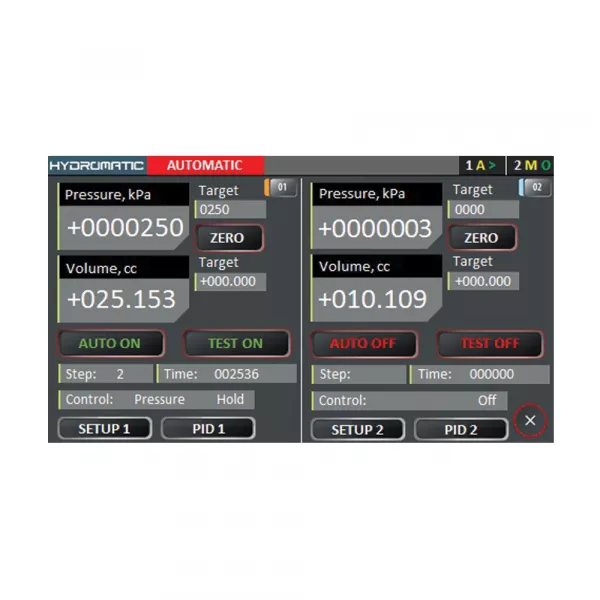

The user-friendly touch screen colour panel allows the local control of pressure showing in real time the pressures readings and the volume changes.

The control panel is mounted on an ergonomic and versatile support adjustable according the user’s preferences:

· fixed on the Hydromatic’s body

· positioned on the triaxial bench close to the testing frame

· ergonomically mounted on the loading frame column by the dedicated support (to be ordered separately).

Volume and pressure data for each line can be saved on the USB pen drive or, as alternative, the Hydromatic can be connected to a GEODATALOG 8 via LAN port and readings will be transmitted to PC with DATACOMM 2 software thus all readings will be synchronized: load cell, displacement and pore pressure transducers, volume change, etc…

Four models are available depending on:

· Maximum pressure capacity: 3500 kPa or 1700 kPa

· Number of pressure lines: one or two.

For a standard effective stress system, a double line Hydromatic is required - one for cell pressure and one for back pressure.

A typical use for a single line Hydromatic is as additional line for permeability test in soil and rock triaxial cells.

Pressure transducer(s) and de airing block(s) are included. Over-travel is prevented by built-in micro-switches.

28-WF43DG

HYDROMATIC standalone closed loop pressure/volume controller. Powers two hydraulic pressure lines and measures the associated volume changes. Max pressure: 1700 kPa. Volume capacity: 250cc.110-220V,50-60 Hz, 1ph.

28-WF43SG

HYDROMATIC standalone closed loop pressure/volume controller. Powers one hydraulic pressure line and measures the associated volume change. Max pressure: 1700 kPa. Volume capacity: 250cc. 110-220V,50-60 Hz, 1ph.

28-WF45DG

HYDROMATIC standalone closed loop pressure/volume controller. Powers two hydraulic pressure lines and measures the associated volume changes. - max pressure: 3500 kPa - volume capacity: 250cc. 110-220V,50-60 Hz, 1ph.

28-WF45SG

HYDROMATIC standalone closed loop pressure/volume controller. Powers one hydraulic pressure line and measures the associated volume change. - max pressure: 3500 kPa - volume capacity: 250cc. 110-220V,50-60 Hz, 1ph.

29-WF4334

Water distribution panel for automatic triaxial testing