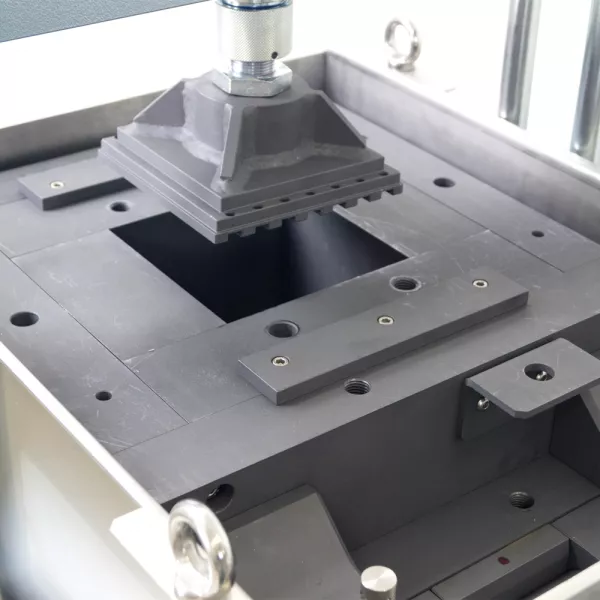

The SHEARMATIC 300 automatic machine is ideal for testing soil and other materials that contain large particles of up to 20 mm largest dimension. Sample size up to 300 mm square can be tested, with inserts allowing the testing of smaller sample sizes. See accessories.

The sample is consolidated via a closed loop hydraulic system for the automatic programmable application of the vertical load. The horizontal displacement is driven by an high resolution stepper motor. The machine is entirely managed by the software of a microprocessor unit that reads the processes of force, axial pressure and displacements, manages the motor, the vertical hydraulic loading system and the test steps through closed loop systems. Ten key scratchproof membrane keyboard with large monochromatic graphic display. The machine work as an automatic stand- alone unit: the test measurements (horizontal and vertical force and displacements) are directly displayed and stored in memory according to pre-set recording modes. The PC is only temporary required to download the test data via the RS 232 serial port, once the test is completed. The data can be processed by the 30-WF6016/T2 or 30-WF6016/T9 Direct and residual Geo-Analysis templates. See accessories.

Using a large sample is possible to gain a more representative indication of shear strength. Furthermore, the large shear box can be used to obtain the angle of friction between many materials. Particular applications include the construction of earth dams and other embankment work.

Shear box completely made of stainless steel is availabe for testing on high corrosive materials.

The machine includes 100 kN load cell and linear potentiometric transducers 100 and 50 mm travel with mounting brackets and shear box.

- Ideal for testing Shale, Industrial slag, Brick rubble, Colliery spoils

- Sample size up to 300

- Two models available with different type of Shear box: in coated steel or in stainless steel for testing high corrosive materials

- 100 kN shear and consolidation force

- Steplessly variable speed control from 0 to 11.00000 mm/min

- Automatic hydraulic application of pre-set consolidation steps (up to 50)

- Automatic test management from consolidation to failure: the operator is only requested to remove the clamping screws of the shear box

- Straight connection between shear box, drive unit and load cell for the axial transmission of the horizontal force along the shearing plane, instead of the classic “swan neck”

- Easy and immediate set up of the test parameters via the large digital graphic display

- Possibility to set different speeds and travel (forward and reverse) in the residual shear tests

- Each single step of axial force can be applied instantaneously or by means of a linear ramp in a pre-set time interval

- Different and independent data recording for consolidation and failure

- Sample size: up to 300 mm. Can be reduced to 150 mm using sample insert (see accessories)

- Sample height: 150 mm

- Shear and vertical force: 100 kN

- Speed range: steplessly variable from o to 11.00000 mm/min

- Maximum travel: 75 mm

- Steps of consolidation: up to 50

- Data acquisition: RS 232 serial port for use with Direct and residual Geo-Analysis templates (see accessories).

- Power: 2000 W

- Overall dimensions: (wxdxh) 1470x758x1570 mm approx.

- Weight approx.: 800 kg

27-WF2304

SHEARMATIC300-Large shear box apparatus 100kN cap. with shear box assembly in treated coating steel for 300mm square sample. 230V/50Hz/1PH.

27-WF2304/INOX

SHEARMATIC300 - Large shear box apparatus 100 kN cap. with stainless steel shear box assembly size 300mm square. 220V/50Hz/1ph

27-WF2304/INOXZ

SHEARMATIC300 - Large shear box apparatus 100 kN cap. with stainless steel shear box assembly size 300mm square. 110V/60Hz/1ph

27-WF2304/Z

SHEARMATIC300-Large shear box apparatus 100kN cap. with shear box assembly for 300mm square sample. 110V/60Hz/1ph

27-WF2304/1

150mm square sample insert for 300mm large shear apparatus

27-WF2304/1S

150mm square sample insert made from stainless steel for Shearmatic300

30-WF6016/T2

Direct and residual Shear Geo-Analysis for MS EXCEL Template according to BS 1377:7

30-WF6016/T9

Direct and residual shear Geo-Analysis template conforming to ASTM D3080

27-WF2304/2

Two additional plates for 300x300 mm made from coated steel for non-granular material

27-WF2304/2S

Two additional plates for 300x300 mm made from stainless steel for non-granular material