Introduction

Gyratory technique basically consists in a compaction of a bituminous mixture contained in a cylindrical mould with the simultaneous action of a vertical static compaction and of the shearing action resulting from the rotation of the mould on its inclined axis. The compaction data is measured and recorded during the test. GYROCOMP gyratory compactors, used for the past twenty years all over the world, are the reference point in terms of user-friendliness combined with reliability and ergonomics, and they have been produced in hundreds of units. Thanks to this experience Controls is introducing the third generation of gyratory compactors with the new GYROCOMP gyratory compactor. The new compactor includes and increases the advantages of the previous models.

Operating principle

The standards specify the method for compaction of cylindrical specimens of bituminous mixtures using a gyratory compactor, Such compaction is achieved by combining a rotary shearing action and a vertical force applied by a mechanical head. The method can be used for:

- The preparation of specimens of given height at a predetermined density, for subsequent testing of their mechanical properties;

- The derivation of a curve density versus number of gyrations;

- The void content for a given number of gyrations.

The standards apply to bituminous mixtures (made both in laboratory or from work site sampling), with aggregates not larger than 37.5 mm.

During operation the bituminous mixture is contained within a cylindrical mould (100 or 150 mm dia.). Compaction is achieved by the simultaneous action of a low static compression and of the shearing action resulting in the motion of the centerline of the test piece, which generates a conical surface of revolution, while the ends of the test piece remain approximately perpendicular to the axis of the conical surface.

Description

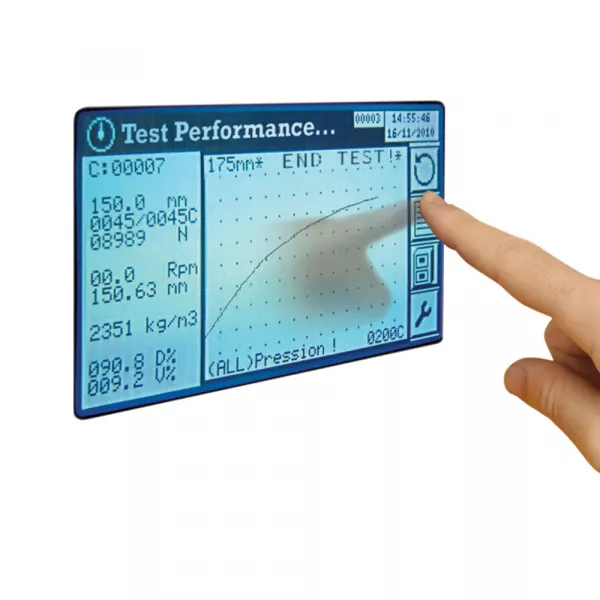

Robust thus light high stiffness steel monocoque structure, incorporating pneumatic cylinder for vertical load application and electromechanical mechanism for the gyration system with exclusive mould rotation system, granting high accuracy and repeteability of test results, together with stiffness and angle stability values widely within the limits defined in EN 12697-31. Touch-screen user-friendly integrated control panel, large display showing the test graph in real time, on board firmware including 12 languages. Possibility to remote test control by PC. The software language can be defined making the interface suitable for any user needs.

The machine can be fit with the electromechanical extruder. See accessories.

The machine is supplied complete with Height calibration tool, PC software, air hose, operating instructions and calibration certificate.

Models preset to ASTM/AASHTO are supplied complete with traceable certificate of load, displacement and internal angle. Models preset to EN are supplied complete with traceable certificate of load, displacement and internal angle, including all the parameters required in EN 12697-31 Annex B (“stability factor”, “parallelism factor”, “full rotation factor”).

The Gyratory compactor GYROCOMP can be used as part of your Superpave performance based testing program.

Cylinder moulds, distance plates and air compressor not included. See accessories.

78-PV2522

GYROCOMP gyratory compactor, internal angle of gyration pre-set to 1.16° to AASHTO T312 and ASTM D6925.110-230V/50-60Hz/1ph

78-PV2522/E

GYROCOMP gyratory compactor, internal angle of gyration pre-set to 0.82°to EN 12697-31 Annex B. 230-110V/50-60Hz/1ph

78-PV0255

ILS device for internal angle measurement for Gyratory compactors, conforming to EN 12697-31, annex B. Complete with Excel Macro and PC connection cable

78-PV0252/14

Integrated work top for 76-B0252 with mechanical specimen extruder

78-PV2520/15

Integrated work top for 76-B252x with motorized (electromechanic) specimen extruder. 230V/50-60Hz/1ph

78-PV2520/15Z

Integrated work top for 76-B252x with motorized (electromechanic) specimen extruder. 110V/60Hz/1ph

78-PV0250/10

Hardened cylinder mould 150 mm dia. with holes for cold mix compaction. Complete with top and bottom plates

78-PV0250/11

Vertical force indicator, complete with 25kN load cell, base, spherical seat, load readout unit and calibration certificate

78-PV0250/13

Stainless steel wearing disc for 150mm dia. gyratory compactor mould

78-PV0250/14

Stainless steel wearing disc for 100mm dia. gyratory compactor mould

78-PV0250/2

Hardened cylinder mould 150 mm dia complete with top and bottom plates.

78-PV0250/3

Distance piece 150 mm dia x 50 mm for low samples

78-PV0250/4

Accessories to compact dia 100 mm specimens. Mould not included.

78-PV0250/5

Hardened cylinder mould 100 mm dia complete with top and bottom plates.

78-PV0250/6

Distance piece 100 mm dia x 38 mm for low samples.

78-PV0250/7

Laboratory air compressor. 220-240V/50Hz/1Ph

78-PV0250/8

Hardened cylinder mould 100 mm dia. with holes for cold mix compaction. Complete with top and bottom plates

78-PV0250/16

Paper discs 150 mm diameter. (pack of 1000)

78-PV0250/17

Paper discs 100 mm diameter. (pack of 1000)