Dynatriax EmS benefits from CONTROLS Group new EmS "Electromechanical Servoactuation" technology.

EmS technology is environmentally friendly and clean to operate, requiring no compressed air or hydraulic oil. It offer excellent reliability, accurate testing and lower maintenance requirements. The intuitive design ensures it can be quickly and easily maintained, only requiring regular lubrication.

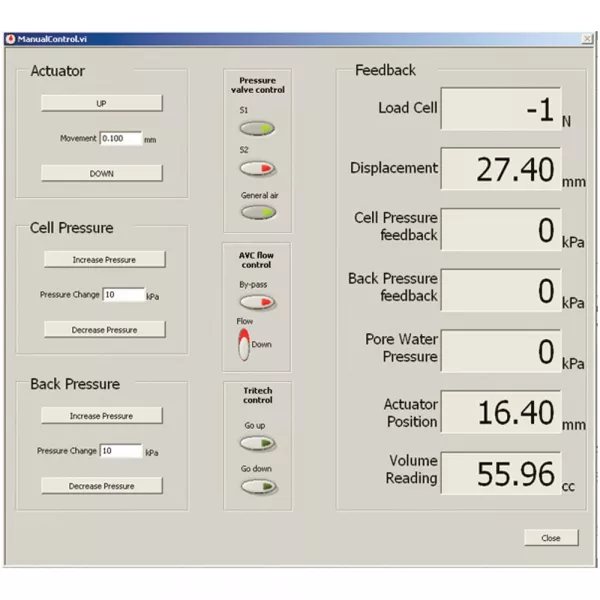

The system controls three closed-loop axes:

- Axial load/displacement

- Cell pressure up to 1000 kPa

- Back pressure up to 1000 kPa

The base system includes:

- Reaction frame

- Robust 2-columns construction, stiff and compact

- Electromechanical vertical load application

- high performance motorized actuator, 15 kN capacity, backlash free and noiseless

- sophisticated PID closed-loop control, ensuring load is reached fast, smoothly and accurately and then maintained with high level of accuracy. The submersible load cell delivers high accuracy from the lowest values

- Data acquisition, process and control

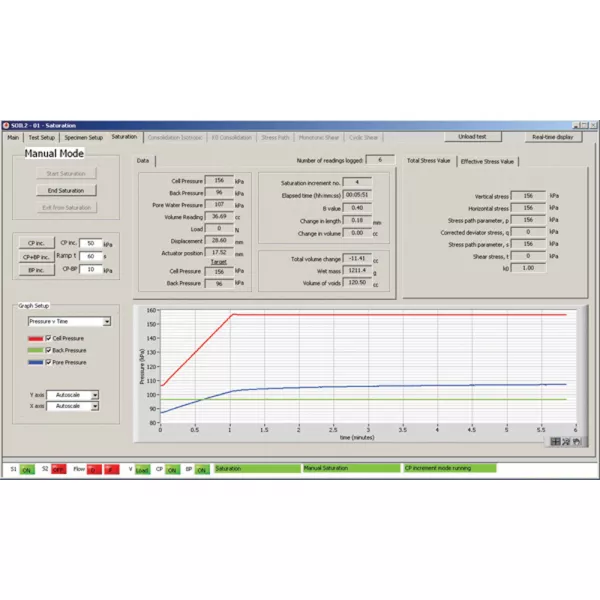

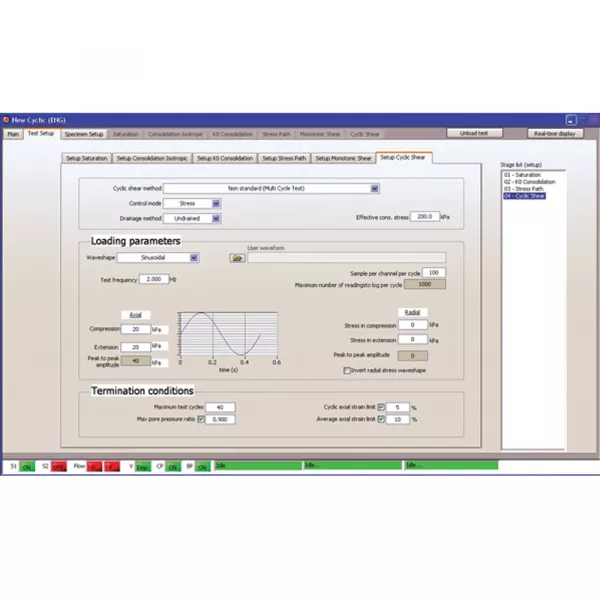

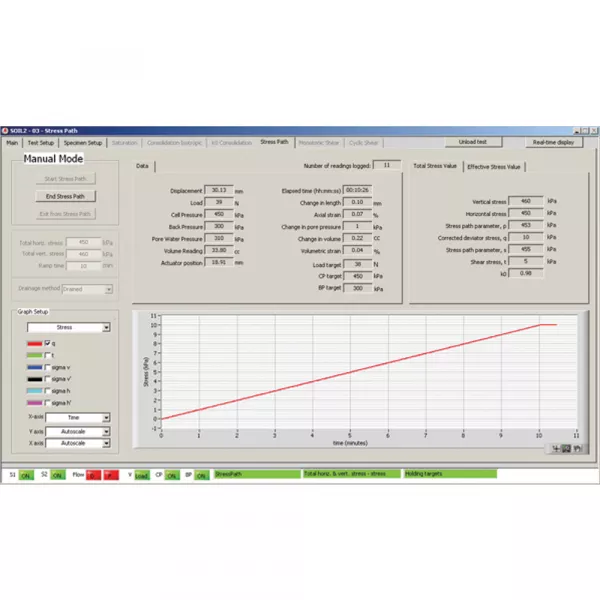

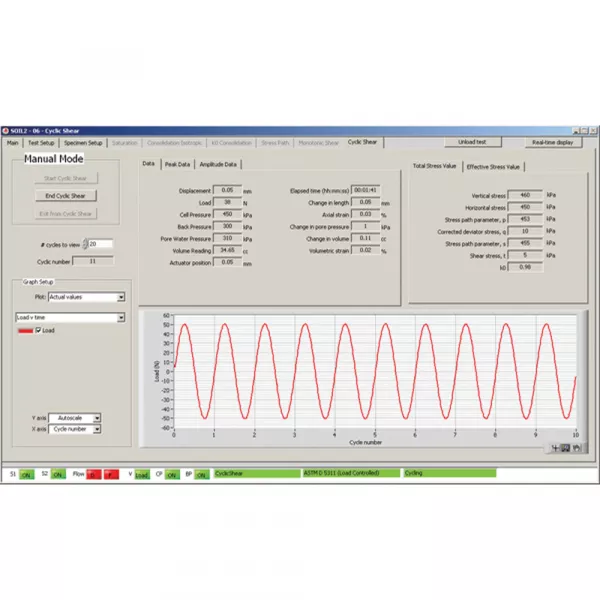

The CDC manages up to 3 closed loop axes (axial load/displacement, cell and back pressure) with an effective loop rate of 10 kHz and performs the test completely automatically including the on/off valves for the drainage line and for the air supply to the triaxial cell. It is linked to the PC via LAN/Ethernet link (1 Gbit/s) and comes with 16 transducer ports (real resolution 16 bit).

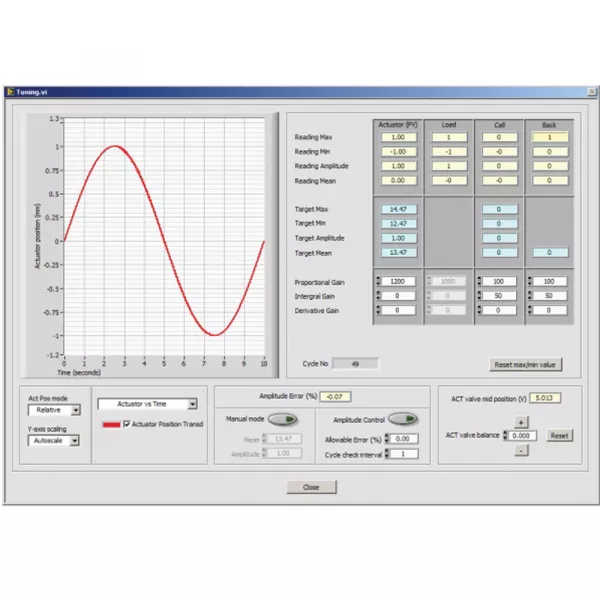

An extremely efficient algorithm with larger gain ranges gives enhanced sensitivity, making it easier to tune the system and achieving a more accurate wave shapes.

Recently added features include manual and automatic amplitude control which compensate for small changes that may occupr in the system during cycling, ensuring that the required peaks are consistently reached. The improved tuning panel, with its more user-friendly interface, provdes all the tools necessary to optimize the system control during static and cyclic test stages.

For a complete test configuration please contact our team of specialist.

- Electromechanical Servoactuation, no need of compressed air or hydraulic power supply for the vertical force

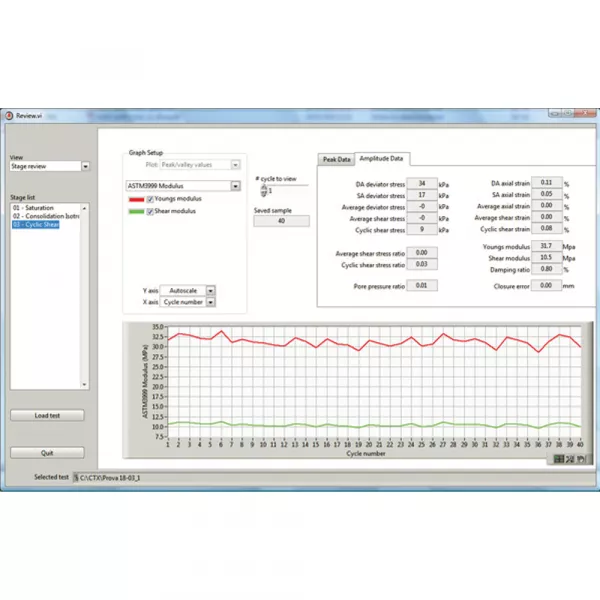

- Capability to perform Static (effective stress and stress path), Dynamic and Unsaturated soil triaxial tests

- Maximum dynamic load: 15 kN

- Maximum static load: 10 kN

- Triple-axes closed loop control of axial load/displacement, cell and back pressure

- Automatic compensation of cell/back pressure during dynamic stage

- Operating frequency more than 10 Hz (depending on test conditions)

- Complete automation of all test stages using an high sensitivity closed loop PID feedback

- Options available for bender elements testing and for local strain transducers

- Standard and user defuned wave shapes which can mimic the real in situ measurements (earthquakes)

- Test set-up by unique programmable multi-stage procedure. When a test is running, it is possible to access all parameters to expand and modify the stages as per the response of the specimen

- Manual and automatic emergency shut off function

- Multitasking, user-friendly Windows-based software pre-installed on the PC

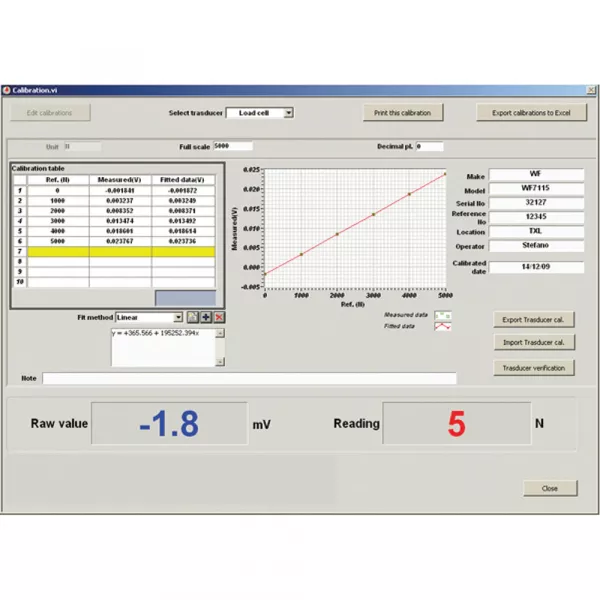

- Extra-accurate transducers calibration adopting linear or polynomial regression or multi-coefficient linearization

- AASHTO T307

- ASTM D5311

- BS 1377:7

- ASTM D2850

- ASTM D4767

- BS 1377:8

- ASTM D7181

- ASTM D3999

- Maximum dynamic load: 15 kN

- Maximum static load: 10 kN

- Maximum vertical travel: 50 mm (different travels available on request)

- Maximum testing frequency: more than 10 Hz (depending on testing conditions)

- Volume change measurement: 100 cc volume change device with automatic flow inversion

- Max sample diameter: 100 mm

- Maximum confining pressure: 1000 kPa

- Maximum back pressure: 1000 kPa

- Close loop control frequency: 10 kHz

- Input channels: 16 - Real resolution 16 bits

- Voltage: 208-230 V, 50-60 Hz, 1 ph or 110 V, 60 Hz, 1 ph

31-WF70E04

Dynatriax EmS - Automatically PC controlled dynamic triaxial system with 15kN electromechanical servoactuation. Supplied complete with PC, CDCtriax control and 16channels data acquisition unit and software. 110V,60Hz,1ph.

31-WF70E06

Dynatriax EmS - Automatically PC controlled dynamic triaxial system with 15kN electromechanical servoactuation. Supplied complete with PC, CDCtriax control and 16channels data acquisition unit and software. 208-230V,50-60Hz,1ph.

31-WF7117

5kN capacity submersible load cell to be used withDynatriax (dynamic triaxial system)

31-WF7118

10kN capacity submersible load cell to be used with Dynatriax (dynamic triaxial system)

31-WF7119

25kN capacity submersible load cell to be used with Dynatriax (dynamic triaxial system)

86-D2015

Laboratory air compressor. 8 BAR max constant pressure. 230V/50Hz/1Ph

29-WF4412

Automatic volume change apparatus allowing remote flow control. Compatible with WF automatic Static/Cyclic triaxial systems AUTOTRIAX/DYNATRIAX

28-WF2016/2

Water Trap for Air/Water assembly

31-WF7121

Axial displacement transducer +/-25mm to be used with Dynatriax (Dynamic Triaxial system)

31-WF7000/RES

Upgrading package for Dynatriax EmS for resilient modulus determination, including software to AASHTO T307, two displacement transducers and mounting braket to fit the transducers to the triaxial cell.

31-WF7000/UNS

Upgrading software package for unsaturated soil testing with Dynatriax EmS including additional servovalve for air pressure control.