The rebound number determined by this method can be used to assess the uniformity of concrete in situ, to delineate zones or areas of poor quality or deteriorated concrete in structures.

This NDT test method is not intended as an alternative for the compressive strength determination of concrete, but with suitable correlations already saved in the instrument, it can provide an estimate of in situ compressive strength. The EN 13791 suggests the procedure for a specific correlation to the concrete under test.

The hammer may be used for comparative testing, referenced against a concrete with known strength or against a concrete verified as conforming to a particular strength class.

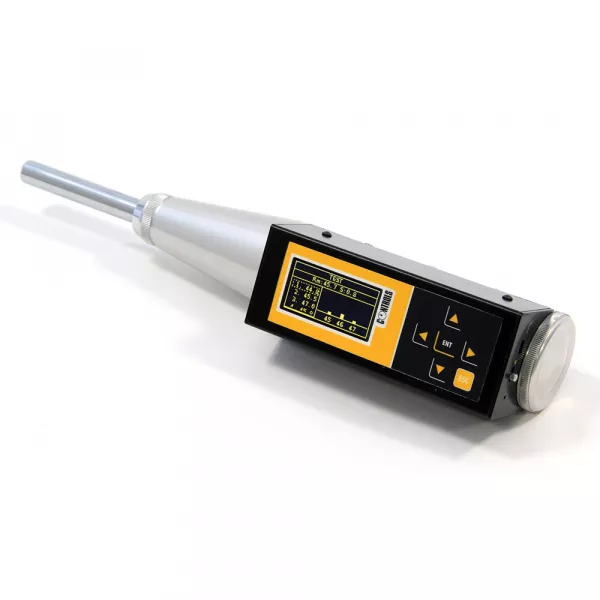

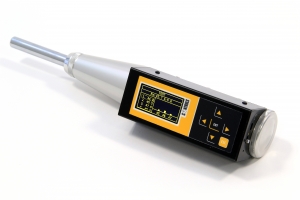

The test hammer 58-C0181/DGT is supplied complete with:

- Multi-voltage/frequency battery charger / with interchangeable plugs compatible with the mote common electrical sockets

- USB cable for PC connection

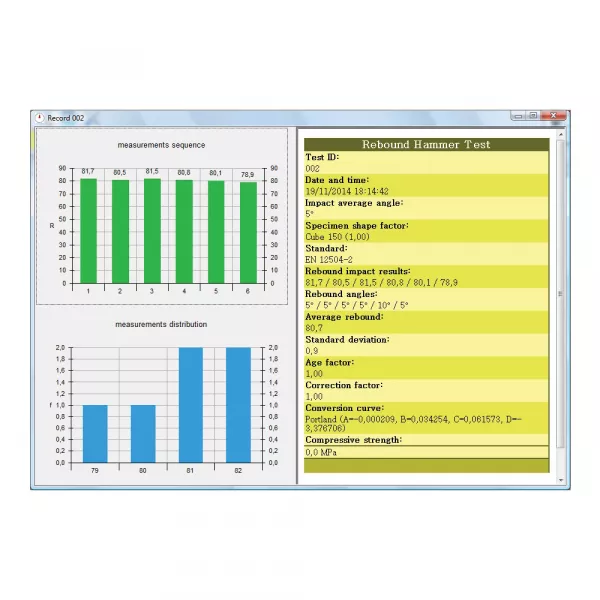

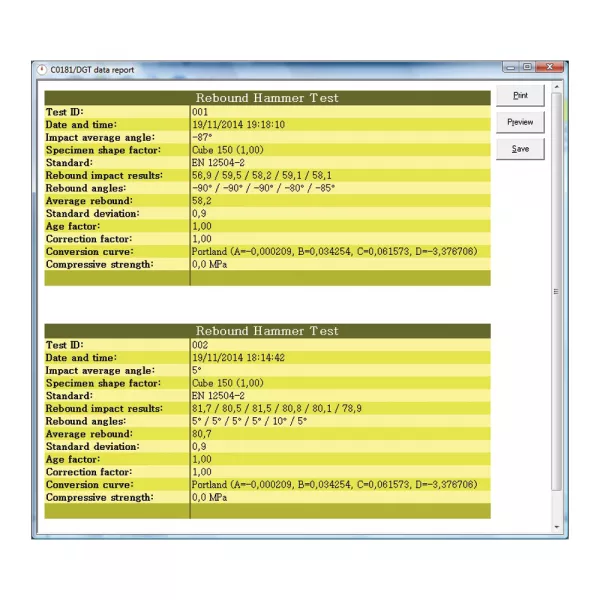

- Dedicated PC software

- Grinding stone

- Carrying case.

The present manual is valid for units having firmware version 1.22 or higher.