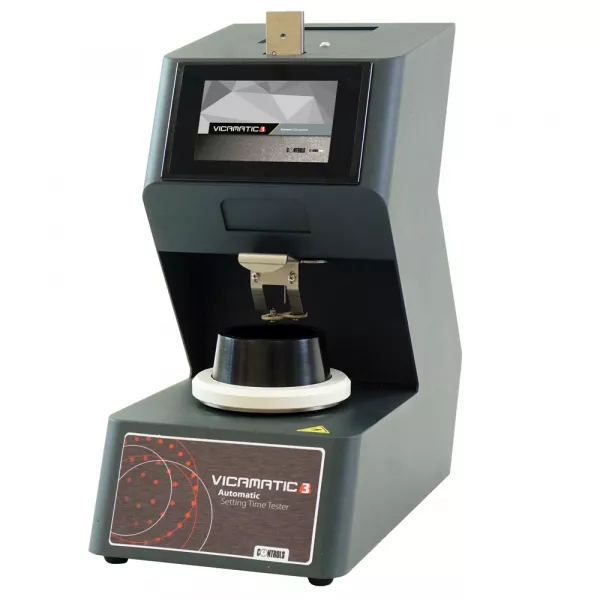

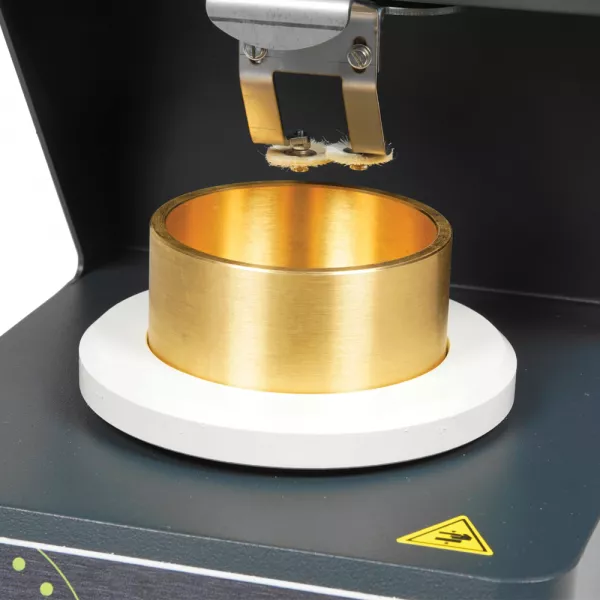

CONTROLS have long tradition in manufacturing automatic setting time testers for cement and mortar. A new generation, the fourth one, is now available, featuring a large color 5.1” touch screen display. As with the older generations the test procedure is unchanged, a needle (or a probe) drops freely into a cement sample at regular intervals and in ?xed positions. Penetration depth is measured by a sensor with 0,1 mm resolution. Along with hardening process development the penetration depth decreases, when it matches some thresholds pre- defined by Standards initial and final setting times are measured and recorded.

- Advanced electronics technologies providing superior performances and total flexibility combined with simplicity in use Easy-to-use double interface: local mode, with large size 5.1" touch screen color display, and remote mode, with PC Supplied complete with PC software for data processing VICASOFT-BASIC

- With PC software VICASOFT-PREMIUM (optional) up to 32 indipendent units (includign VICAMATIC 2 models) can be connected t

- single PC via LAN port and hub. All units are remotely controlled. Adopting the multi-test network concept laboratory productivity is maximized

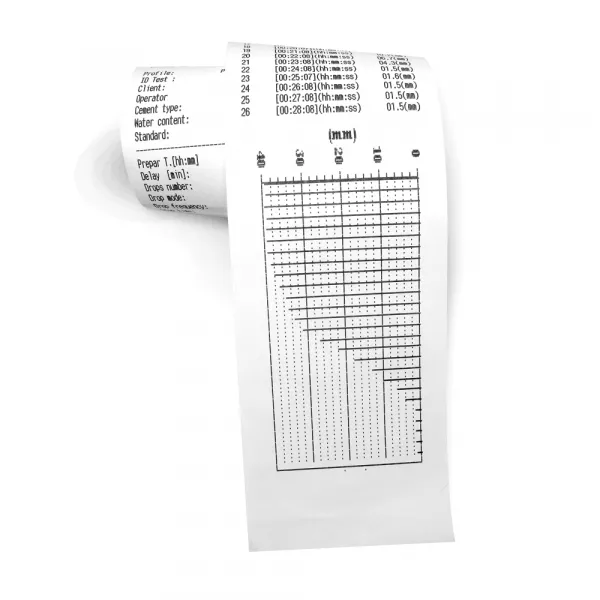

- Integrated graphic printer is available as optional accessory showing both results in numerical format and setting time plot Easy setting and storage of user-defined test profiles allowing quick test start

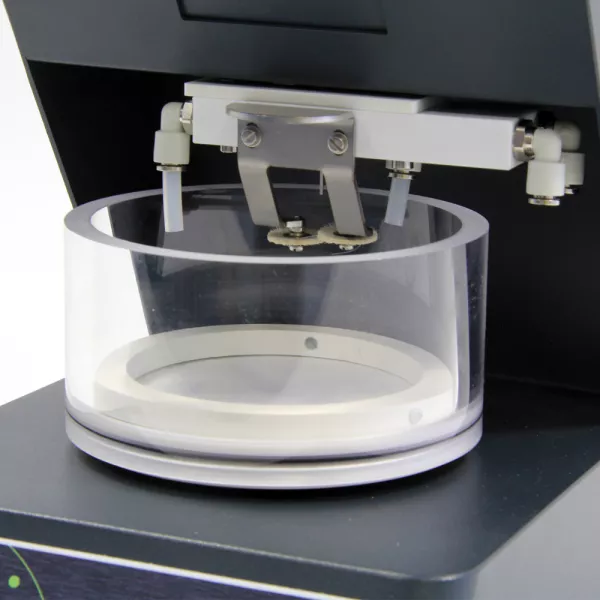

- Large accessibility to the test space Complete with needle cleaning device Practical in-water testing accessory (optional)

- Automatic determination of initial and final setting time

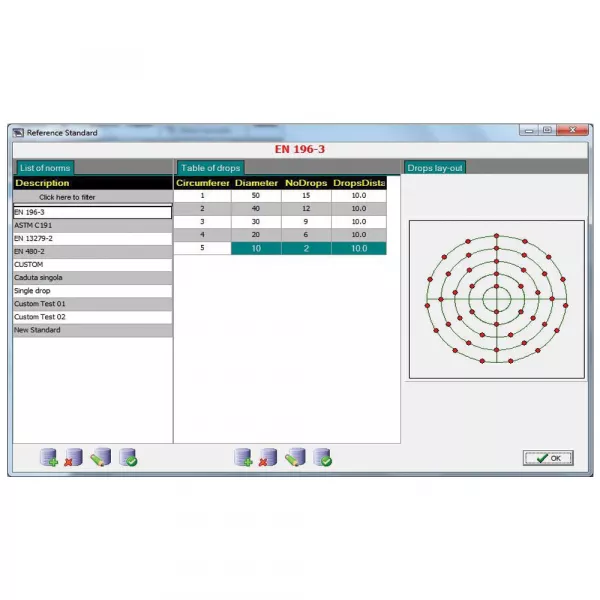

- EN 196-3

- EN 480-2

- ASTM C191

- AASHTO T131

- ASTM C451

- EN 13279-2

- ASTM C807

- ASTM C187

Conforming to EN 196-3, 13279-2, 480-2, ASTM C191, C187

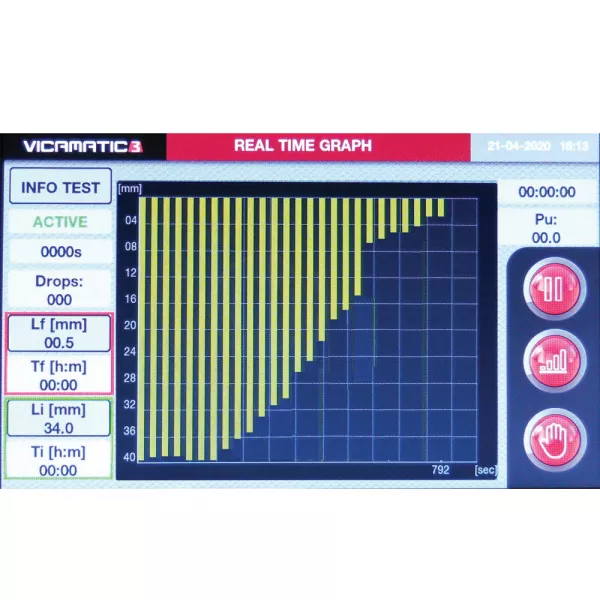

5.1”, 800 x 480 pixel, 16 M colors, icon-driven touchscreen graphic display, showing data and plots

LAN port for direct connection to PC of a single unit or connection to a LAN hub for creating a network with up to 32 independent units all controlled by a single PC. 1 LAN cable is included

USB port for test data download to PC and easy firmware upgrade Unlimited storage capacity for test data on internal 16 GB SD card

Test procedures can be customized and stored to match user-defined requirements Can incorporate an integrated graphic printer showing test result and setting time plot Large test space with easy accessibility

Automatic calculation of initial and final setting time at programmable penetration depth limits

Wide range of accessories including EN and ASTM/AASHTO parts, in-water testing kit, needle cleaning device, integrated printer, probes for testing consistency and gypsum

Minimum penetrations rate: 10 seconds Penetration measurement by encoder Power: 50 W

Dimensions: 200x400x410mm (L x W x H)

Weight approx.: 10 kg

Firmware specifications

- Easy programming of customized test profiles, recallable for future tests, including:

- adjustable test start delay

- penetration points positions

- manual or automatic penetration rate

- free or driven dropping mode

- holding intervals inside the sample

- automatic end- test detection

- automatic measurement of initial and final setting time

- Test data: test number, operator, client, date, hour, cement type, water percentage, delay Easy calibration menu

- Clock calendar Multi-language

- automatic measurement of initial and final setting time

- Test data: test number, operator, client, date, hour, cement type, water percentage, delay Easy calibration menu

- Clock calendar Multi-language

63-L2701/E

VICAMATIC-3, automatic electronic apparatus for setting time test on cement/mortar/gypsum. Complete with EN 196-3 accessories: initial Setting time needle 1.13 mm dia. and mould.

110-240V, 50-60Hz, 1ph.

63-L2701/F

VICAMATIC-3, automatic electronic apparatus for setting time test on cement/mortar/gypsum. Complete with ASTM C191 accessories: initial setting time needle 1 mm dia. and mould.

110-240V, 50-60Hz, 1ph.

63-L2701

VICAMATIC-3, automatic electronic apparatus for setting time test on cement/mortar/gypsum. Supplied without accessories (mould, needle) and mould cenetering ring.

110-240V, 50-60Hz, 1ph.

63-L2700/E10

Accessory for in-water testing.

63-L2700/E11

LAN HUB for PC connection of up to 7 VICAMATIC units or up to 6 units in case of multi-hub network. LAN cable from hub to PC is included. Each VICAMATIC unit is supplied complete with LAN cable

63-L2700/E14

Needle for final setting test to EN

63-L2700/E15

Cylindrical probe for consistency test

63-L2700/E16

Additional weight 700 g (EN 480-2)

63-L2700/E18

Conical penetration probe 8 mm dia x 50 mm complete with 100g calibrated weight for gypsum testing to EN 13279

63-L2700/E20

1,13 mm diameter needle to EN

63-L2700/E9

Water thermostatic unit for up to 2 VICAMATIC units. 230V/50-60Hz/1ph

63-L2700/E9Z

Water thermostatic unit for up to 2 VICAMATIC units. 110V/60Hz/1ph

63-L2700/F15

Cylindrical probe and additional weight for consistency test to ASTM C807

63-L2700/PR

Upgrading of a VICAMATIC unit for incorporating a graphic printer into the head. Test settings and results are plotted both as numerical and graphical format including penetration depth/time diagram. The upgrading shall be factory installed.

63-L2700/1

Centering ring for EN mould

63-L2700/2

Centering ring for ASTM mould

63-SW/VS

VICASOFT-PREMIUM PC software to connect up to 32 VICAMATIC-2 units including remote control of eachunit, data acquisition - processing - filing, printout of test reports.

63-L0027/E22

Plastic mould to EN

63-L0027/E23

Plastic mould to ASTM/AASHTO

63-L2700/E21

1mm diameter needle to ASTM/AASHTO

63-L2700/E24

Glass base plate

63-L2700/E25

Spare base plate for in-water testing kit

63-L2700/F21

2mm diameter needle to ASTM C807

63-L2700/F23

Brass mould dia.76mm x 40mm to ASTM C807

63-L2700/1

Cenitering ring for EN mould

63-L2700/2

Centering ring for ASTM mould

63-L2700/E20

1,13 mm dia. needle for initial setting time test to EN