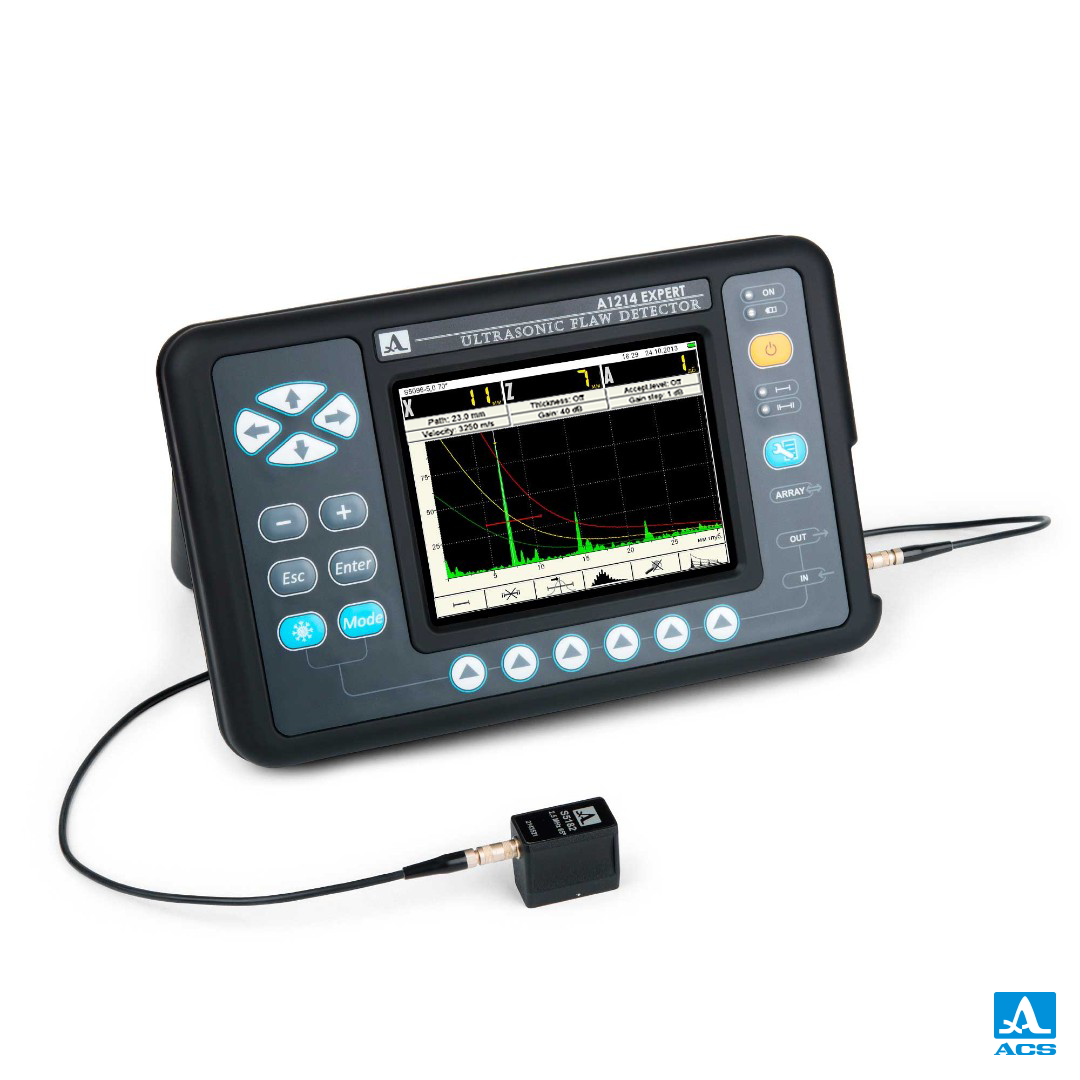

Classic version of an ultrasonic flaw detector offering all up-to-date functions.

Large high-contrast color TFT display with high resolution (640 x 480) enables you to work for a long time without straining your eyes.

User-friendly interface with shortcut keys.

Quick-detachable frost-resistant accumulator.

A1214 EXPERT flaw detector offers a range of unique features thanks to entirely digital paths:

The signal can be represented in undetected form – RF type signals (radio signal) in real time, making it possible to examine signal phases in details, to perform testing with a lot of structural noises and to distinguish signals from nearby reflectors.

Quick access to control functions.

At any operation mode the lower part of the screen features an icon menu to access set up and functions quickly.

Large library of configurations (100 variants).

The device can be customized for various situations and objects in a lab, and on-site the operator can just select the right configuration from the menu. All settings are saved in the nonvolatile memory.

Energy – independent memory for 2000 display images (A-scans with settings of inspection).

At the MENU mode the signal and its description is shown at the upper part of the display allowing to adjust settings of inspection on-the-fly.

Voice comments can be added to saved imaged with the help of freehand Bluetooth set. (2000 options).

Within 20 seconds the user is able to record the necessary information about the test object with a reference to a frame of saved A-Scan.

Semiautomatic procedure of angle correction and delay time in the wedge in case of transducer wearing.