Featuring almost the same performances of the HPU 200 Series at a more affordable price thanks to the application of the AUTOMAX T technology.

High flexibility covering the following applications:

- Steel

- Tensile tests on steel rebars and rounds up to 50 mm dia.

- Tensile test on steel flats up to 60 x 90 mm

- Tensile tests on wire strands and electro-welded steel screen

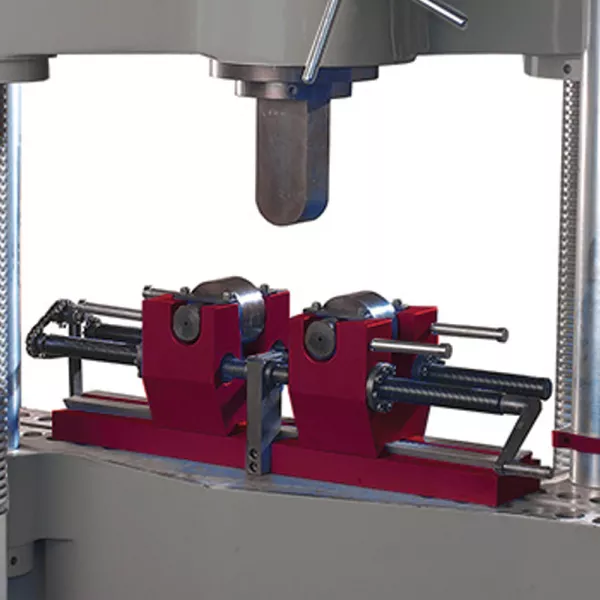

- Transverse tests on steel specimens

- Bend and re-bend tests on steel specimens

- Brinnel with 10mm ball

- Shear tests on rounds

- Concrete

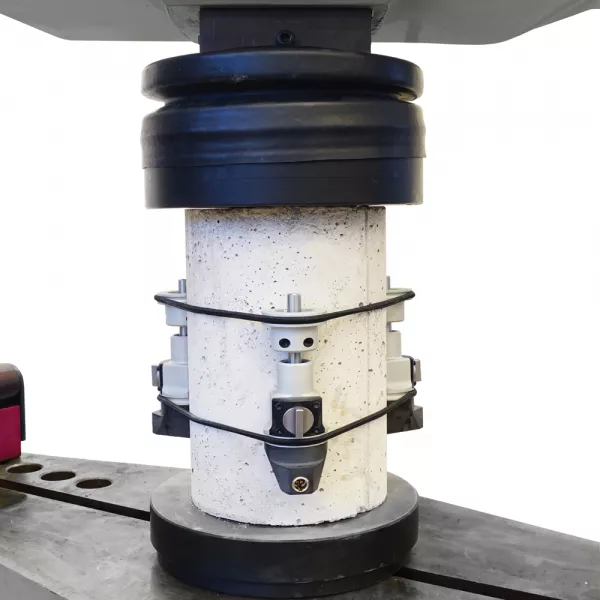

- Compression tests on cubes and cylinders

- Flexural tests on concrete beams

- Indirect tensile on cylinders, cubes and paving blocks

- Determination of the Modulus of elasticity

- Pull out test

- Various

- Compression tests on rock, masonry units, refractories etc.

- Wire rope tensile tests

- Nut and bolt testing

- Tensile test on headed and shouldered specimens

This model is controlled by the new AUTOMAX T control unit and is complete with PC, upper and lower hydraulically operated jaws, complete set of grips for rounds and flats, transverse test attachment and high precision load cell providing high accuracy from the very beginning of the load scale.

Loading frame

The frame consists essentially of a robust four columns frame with three sturdy crossheads: upper is directly connected to the lower one by two main columns; the middle one, moving on two screw columns, can be adjusted through an electric motor by using the dedicated push button panel, in order to set the required vertical daylight both for compression and tensile tests; the lower is controlled by a simple effect piston centrally positioned. Jaws and wedge grips are included. The tensile jaws are operated by a separate Hydraulic Gripping System with dedicated a push-button panel. The compression tests are performed between the lower and the mobile middle crossheads, using the suitable accessories.

Power and control console - Automax T

Control console AUTOMAX T features space-saving ergonomic design with small footprint and houses the hydraulic power unit, the electronic system and the PC to manage all the control functions.

Automatically performs steel tensile testing, compression, splitting tests, Elastic Modulus and Poisson's ratio determination on concrete specimens. See Accessories.

PC and software enable remote control of the complete system.

For more info see Technical Specifications.

Safety features

- Pressure valve that automatically stops the machine when the oil pressure approaches the limit

- Maximum travel limit switches to control the position of the mobile crosshead

- Software stops the machine when the maximum load is reached

- Emergency stop button

- HIGH FLEXIBILITY

Performs both tension tests on steel rounds and flats, and compression/transverse/splitting/elastic modulus tests on concrete

- RUGGED FOUR COLUMN FRAME

Extremely rigid four column frame with large vertical clearance suitable for tension and compression tests

- FRONT OPEN CROSSHEAD

For easy insertion of tensile specimens. The jaws and grips can be easily removed by just pulling from the front. Hydraulic gripping system operated by push button panel

- HIGH ACCURACY WITH LOAD CELL

Load measurement by high precision load cell providing high accuracy from the very beginning of load scale.

- FULL RANGE OF ACCESSORIES

available to perform various tests, including Extensometers, Transverse and Bending test apparatus for steel, Compression-Flexural and Indirect tensile test on concrete, etc.

- PC CONTROLLED

Completely automatic test execution

- SOFTWARE PACKAGES INCLUDED

Supplied complete with management software and software packages concerning wide range of tests on steel, concrete and other construction material.

- EN ISO 6892

- EN ISO 7500-1

- ASTM A370

- EN ISO 15630-1

1 Max distance between grips to exploit the full piston travel

2 Other voltages: For 220 V, 60 Hz, 3 ph, from 2 to 4

AUTOMAX T POWER AND CONTROL CONSOLE

Hardware

- 131.000 points effective resolution

- Control frequency 250 Hz;

- Sampling rate 250 Hz;

- Closed-loop P.I.D.control

- 6 channels (one dedicated to crosshead displacement) to measure elongation/displacement/strain with Potentiometric, conditioned LVDT and magnetostrictive transducers

- 4 channels for strain measurements with strain gauges

- 1 channel for load cell

- simple multi-sensors connection and calibration file selection

- digital linearization of the calibration curve. (multi-coefficient)

Hydraulics

- Dual stage pump: centrifugal low pressure for fast approach (max. flow rate 2.5 l/min ) automatically switching to radial multi- piston high pressure (max. flow rate 0.9 l/min) for loading

- DC motor 1100 W

- Maximum working pressure 700 bar

- Flow sharing technology to perform loading and unloading cycles

- ES Energy saving technology to control the oil flow by regulating the DC mo9tor speed

- Efficient noise reduction cabinet

- Oil tank capacity 9 l

MANAGEMENT SOFTWARE AND SOFTWARE PACKAGES

HPT Universal testers are supplied complete with RTM (Real Time Management) user interface environment allowing:

- Remote control of the complete system for automatic test execution: quick platen approach, zeroing, test execution according to the selected test type, calculation of results, graphical and numerical management of results

- Storage of single and multiple tests

- Printing of customized test reports for both single and multiple tests

- Real time and deferred management of tests data and results, either in numeric or in graphic format

- Language selection (Latin characters only)

- Units selection

- Remote technical assistance/diagnostic via internet

The following Software packages are also included in the system:

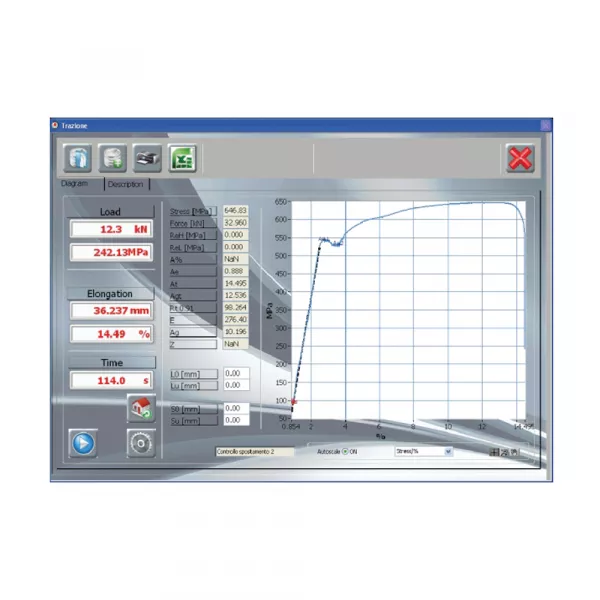

- UTS Software Specifically designed for tensile testing under load/stress control and crosshead separation control (by using the displacement transducer supplied with the machine), allowing:

- Simultaneous display of stress/time, stress/elongation %, elongation/time and stress/elongation;

- Possibility to overlap two elongation/stress graphs: one obtained with the included displacement transducer measuring crosshead separation travel and the other obtained w ith an optional extensometer (coaxial or universal);

- Elaboration of tension test results: ReH, ReL or Rp (calculated at three different elongation percentages selectable by the user), A, Ag, At, Agt, Ae, Rt, Z, elastic modulus E, etc, conforming to EN ISO 6892-1 and EN 15630-1 for steel rebars.

- DATAMANAGER Software For compression, flexure and indirect tensile test on concrete, cement specimens and other construction materials allowing:

- Real time monitoring of test data and stress/time graph

- Automatic load detection failure and storage

- Cement testing to EN 196-1 guided test procedure

- Saving of batch file with automatic calculation of average and standard deviation

The following software package is available as option (82-SW/EM):

- E-MODULE software For Poisson ratio and Elastic Modulus determination on concrete specimens allowing:

- Free unlimited programmable load/stress cycles to fulfill any kind of test procedure

- Real time monitoring of test data, stress/time, stress/axial strain, stress/lateral strain graphs

- Automatic verification of sample centering and sensors functionality, as per Standard requirements

- Automatic calculation of Initial and Final secant Elastic Modulus values

UT100-AUTOMAX-HG

Automatic Computerized Universal Testing Machine, 1000 kN cap. AUTOMAX T control console. Load measurement by high precision load cell. Supplied complete with PC, upper and lower hydraulically operated front open jaws, inserts sets for Round samples (Dia.), 12 - 30, 30 – 46, 46 - 60 mm and Inserts sets for flat samples, sizes : 0 - 20, 20 – 40, 40 - 60 mm (accepts samples up to 90 mm wide) and transverse test attachment. Including also Management software and Software packages for tensile steel testing, compression flexural and indirect tensile testing on concrete and other similar materials. 380 V, 50 Hz, 3 ph.

55-C0222/H

Electronic universal extensometer/compressometer for cylinders, prisms and cubes. Suppied with short distance piece for use with prisms 40x40x160 mm and 2 elastic bands

70-C0954/C1

Electronic universal extensometer to measure the elongation of wires, steel rebars and round steel specimens. To be removed before sample failure. - Measuring base: 50 to 200 mm - Linearity: better than +- 1% - Max. travel: 10 mm

50-SW/EM

E-MODULE software package for Elastic modulus and Poisson ratio determination.

70-C0961/E

Coaxial electronic extensometer to measure the elongation of wires up to failure. Gauge length: 600mm; Max travel: 50mm

70-C0961/G

Coaxial electronic extensometer for round specimens from 16 to 40 mm dia. Gauge length: 200 mm. Travel: 75 mm.

70-C0961/H

Coaxial electronic extensometer for round specimens from 6 to 26 mm dia. Gauge length: 200 mm. Travel: 50 mm.